Brief introduction of latex glove Technology

点击:发布日期:2020/9/23

The rubber is first sliced by the rubber mixer, and then sent to the sol cylinder to mix the sol with gasoline. After emulsification and modulation, the sol is pumped to the emulsion tundish. The rubber solution dissolved in gasoline is sent from the top of the distillation tower and distilled by steam heating. The light component gasoline is heated into a gas phase, and the gasoline gas is mixed and cooled by cold water in the oil-gas cooler. The oil-water mixture goes to the oil-water separator and the oil-water is separated. The upper gasoline is recovered, and the lower water is pumped to the cooling tower for cooling. After cooling, the gas gasoline in the distillation tower is cooled. The latex at the bottom of the distillation tower is sent to the emulsion mixing tank according to its own pressure for mixing and mixing. After mixing and mixing, the latex is separated from the glove raw material by the centrifuge, and then it is used after color matching and filtering.

The glove model is first cleaned by acid and alkali, and then washed with water. The cleaned model is immersed in hot water and heated until it is soaked in coagulant and dried. After dipping, it is sent to the oven for preliminary drying, adding fiber inner sleeve, flushing hot water, and then to the oven for curing and drying. After demoulding, the gloves should be inflated for inspection, set at low temperature, dried at medium temperature, washed, dehydrated and dried, and then packed and sent to the finished product warehouse.

The glove model is first cleaned by acid and alkali, and then washed with water. The cleaned model is immersed in hot water and heated until it is soaked in coagulant and dried. After dipping, it is sent to the oven for preliminary drying, adding fiber inner sleeve, flushing hot water, and then to the oven for curing and drying. After demoulding, the gloves should be inflated for inspection, set at low temperature, dried at medium temperature, washed, dehydrated and dried, and then packed and sent to the finished product warehouse.

V100 vinyl disposable gloves

ND100 nitrile disposable gloves

F301 cup face mask

F300 cup face mask with activated carbon

F202 KN95 face mask

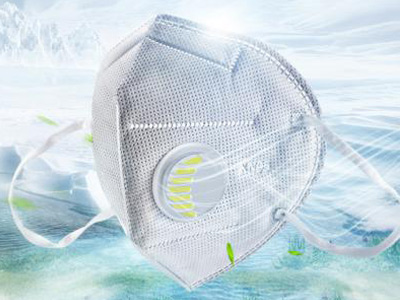

F201 KN95 face mask with valve

F200 FFP2 NR 4ply face mask

F102 children 3ply disposable face mask

F101 disposable face mask with activated carbon

F100 3ply disposable face mask

The method of judging whether the film glove penetrates

Maintenance methods of PVC labor protection gloves

The difference between latex gloves and rubber gloves

Latex glove material

Characteristics of latex gloves

Brief introduction of latex glove Technology

Film quality determines the quality of film gloves

Performance of film gloves