Latex glove material

点击:发布日期:2020/9/23

Gloves are divided into cotton yarn, plush, leather, etc. The material commonly used to make gloves is fiber.

Lining: PVC for heat protection design

Point molding -- the best anti slip scheme

Pu or latex coating --- suitable for oil or oil environment.

Several commonly used glove materials:

(1) Metal wire - common stainless steel wire, but also chromium alloy wire, mainly used to make cutting resistant gloves. This kind of material has the strongest cutting resistance and is easy to clean, but it is heavy and inconvenient to use.

(2) Kevlar, spectra and other synthetic yarns are also better materials for cutting resistance of synthetic fibers. Although the cutting resistance is not as good as that of metal wires, they are light in weight and comfortable to use. After improvement and treatment, some products can reach the highest level of anti cutting product standards.

(3) Nitrile (with fabric lining) - wear and puncture resistance, flexible and comfortable to use.

(4) Natural latex (with fabric lining) - it has excellent elasticity, especially flexibility, and has certain abrasion resistance, tear resistance and cutting resistance.

(5) PVC (with fabric lining) - can provide a certain degree of wear and puncture protection, if the material is thick, it can also have a certain cutting resistance, but not tear resistance.

(6) Leather - natural material, through a variety of tanning treatment, has a unique performance. Leather can be divided into: cowhide, which has the advantages of comfort, durability, air permeability and wear resistance. After chrome treatment, it is more durable and can resist high temperature; pigskin, with large pores, has the best air permeability, and can still maintain good softness after washing without hardening; sheepskin is the most comfortable, most durable and wear-resistant, but due to its high price, it is generally only used for touch requirements Higher industries.

Lining: PVC for heat protection design

Point molding -- the best anti slip scheme

Pu or latex coating --- suitable for oil or oil environment.

Several commonly used glove materials:

(1) Metal wire - common stainless steel wire, but also chromium alloy wire, mainly used to make cutting resistant gloves. This kind of material has the strongest cutting resistance and is easy to clean, but it is heavy and inconvenient to use.

(2) Kevlar, spectra and other synthetic yarns are also better materials for cutting resistance of synthetic fibers. Although the cutting resistance is not as good as that of metal wires, they are light in weight and comfortable to use. After improvement and treatment, some products can reach the highest level of anti cutting product standards.

(3) Nitrile (with fabric lining) - wear and puncture resistance, flexible and comfortable to use.

(4) Natural latex (with fabric lining) - it has excellent elasticity, especially flexibility, and has certain abrasion resistance, tear resistance and cutting resistance.

(5) PVC (with fabric lining) - can provide a certain degree of wear and puncture protection, if the material is thick, it can also have a certain cutting resistance, but not tear resistance.

(6) Leather - natural material, through a variety of tanning treatment, has a unique performance. Leather can be divided into: cowhide, which has the advantages of comfort, durability, air permeability and wear resistance. After chrome treatment, it is more durable and can resist high temperature; pigskin, with large pores, has the best air permeability, and can still maintain good softness after washing without hardening; sheepskin is the most comfortable, most durable and wear-resistant, but due to its high price, it is generally only used for touch requirements Higher industries.

V100 vinyl disposable gloves

ND100 nitrile disposable gloves

F301 cup face mask

F300 cup face mask with activated carbon

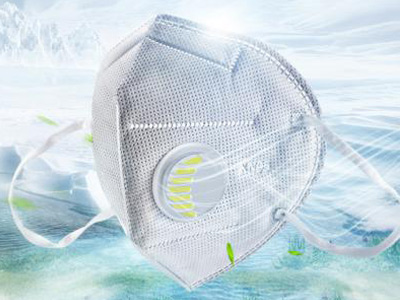

F202 KN95 face mask

F201 KN95 face mask with valve

F200 FFP2 NR 4ply face mask

F102 children 3ply disposable face mask

F101 disposable face mask with activated carbon

F100 3ply disposable face mask

The method of judging whether the film glove penetrates

Maintenance methods of PVC labor protection gloves

The difference between latex gloves and rubber gloves

Latex glove material

Characteristics of latex gloves

Brief introduction of latex glove Technology

Film quality determines the quality of film gloves

Performance of film gloves